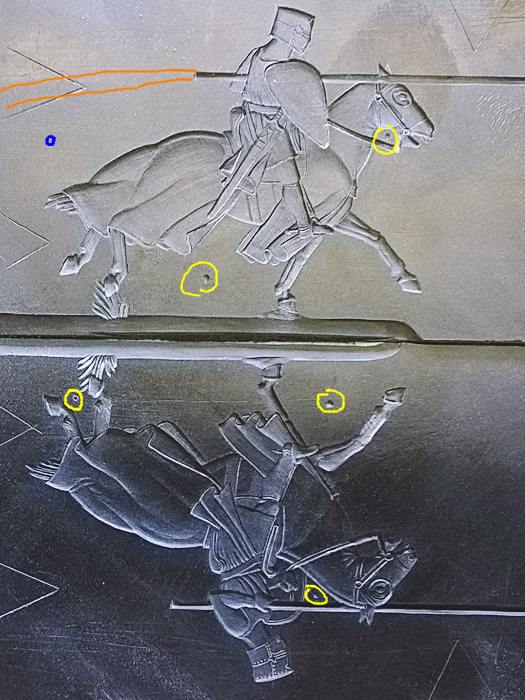

The engraving of a tin figure

Tin figures are engraved in slate by a special engraver for tin figures. There are very few who have mastered this art. The engraver for tin figures first needs the drawing of an illustrator on tracing paper. First, the outlines of the figure are transferred from this template to the slate.

Fine gravers are then used to engrave in a slight depression on highly polished slate. Parts that are later raised must be deeply engraved in the stone. The engraver works both depthwise and mirror-inverted. Both halves of the stone for the front and the back must fit together exactly to the millimetre.

Master engraver Regina Sonntag in her workshop engraving the figure.

First, the outlines of the figure are transferred from the drawing onto the slate.

Engraving in slate requires strength and skill.

Tools and casting furnace. All channels are now laid for the perfect cast.

The cast

Tin figures are made of an alloy of tin, lead, antimony and bismuth. Every engraver has his own special recipe. In order for the metal to penetrate the finest recesses, flow in quickly and allow the air to escape, the engraver has to draw casting channels and air holes, the "islands" as well as, cobweb-like channels, the "pipes" with a drawing needle. Special knowledge and skill are also indispensable for this.

The deburring

Metal residues from the cast that still adhere to the figure are removed with the smallest needle files and a scalpel. The most careful work is required here, because otherwise the figure can quickly be damaged. Each individual figure is treated in this way by hand. This is also referred to as "cleaning" the figure.